Protecting Surgical Instruments: Common Threats and Best Practices. In the healthcare industry, surgical instruments are indispensable tools that play a pivotal role in the success of medical procedures. Ensuring their longevity and optimal performance is essential for patient safety and the effectiveness of surgeries. To achieve this, healthcare professionals must be aware of the potential threats that can damage surgical instruments. Here, we explore some of these threats and best practices to mitigate them:

1. Corrosion

Corrosion can compromise the integrity of surgical instruments, posing risks to both patients and healthcare providers. It often results from exposure to moisture, harsh chemicals, or improper cleaning and sterilization methods. To prevent corrosion, instruments should be cleaned and sterilized using approved solutions and methods.

2. Improper Handling

Protecting Surgical Instruments: Common Threats and Best Practices. Rough handling, accidental drops, or using instruments for unintended purposes can lead to dents, bends, or fractures, rendering them ineffective and hazardous during surgery. Proper handling and care are crucial to avoid such damage.

3. Inadequate Cleaning and Sterilization

Failure to clean and sterilize instruments correctly can lead to the accumulation of biofilms, debris, or residue, increasing the risk of infection and instrument deterioration. Following stringent cleaning and sterilization protocols is paramount.

4. High Temperatures

Autoclaving at temperatures higher than recommended can cause heat-related damage, including warping, discoloration, or the loss of temper in the metal. Adhering to temperature guidelines during sterilization is essential to maintain instrument reliability.

5. Incompatible Chemicals

Exposure to strong or incompatible chemicals can result in instrument discoloration, staining, or corrosion. Utilizing only approved cleaning and disinfection solutions is imperative to prevent chemical damage.

6. Prolonged Exposure to Blood and Tissues

Promptly cleaning and rinsing instruments after use is crucial to prevent the drying and hardening of biological materials, which can lead to corrosion. Swift and effective cleaning is key to preserving instrument quality.

7. Inadequate Maintenance

Regular inspection, maintenance, and sharpening of cutting instruments are essential to ensure precision and effectiveness over time. Neglecting these aspects can lead to a decline in instrument performance.

8. Low-Quality Materials

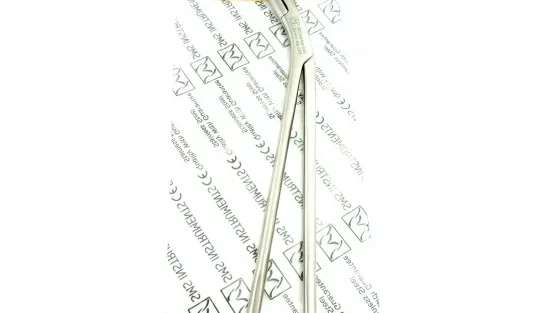

Instruments made from inferior materials or craftsmanship are more prone to damage and may not withstand the rigors of surgery. Investing in high-quality SMS instruments is a wise choice to ensure durability and reliability.

9. Environmental Factors

Storage conditions, such as excessive humidity or exposure to extreme temperatures, can have detrimental effects on surgical instruments. Maintaining an appropriate storage environment is crucial to prevent environmental damage.

10. Frequent Reprocessing

Instruments designed for single-use should not be repeatedly sterilized and reused, as this can compromise their structural integrity. Adhering to guidelines for single-use instruments is essential for patient safety.

Adhering to stringent protocols in the cleaning, sterilization, and storage of surgical instruments is a linchpin in mitigating potential risks and ensuring their pristine condition. Incorporating cutting-edge technologies and innovative materials in the manufacturing process further contributes to the durability and resilience of these critical instruments. The fusion of advanced materials, coupled with the implementation of state-of-the-art design principles, not only enhances the longevity of surgical instruments but also elevates their precision, thereby positively impacting surgical outcomes.

The ripple effect of prioritizing surgical instrument care extends beyond the operating room, resonating with broader healthcare safety initiatives. This commitment to excellence in maintenance aligns seamlessly with the overarching goal of promoting patient well-being. As custodians of medical equipment, healthcare providers assume a pivotal role in fostering a culture of responsibility and diligence, where every action undertaken in the context of surgical instrument care directly translates into a safeguarding of patient safety.

Protecting surgical instruments is a responsibility that healthcare providers must uphold. By understanding these potential threats and implementing best practices, we can ensure the longevity and effectiveness of these critical tools, ultimately contributing to the success of surgical procedures and patient well-being. #SurgicalInstruments #HealthcareSafety #MedicalEquipment #PatientSafety #SurgicalInstrumentCare #NazmedSMS #SMSInstruments