Description

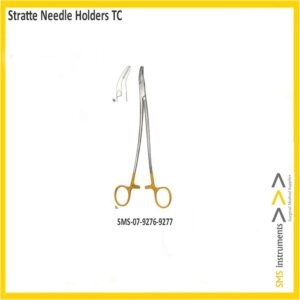

Ryder Needle Holders TC

SMS instruments Ryder Micro Needle Holder is a ratcheted, finger ring instrument that features narrow jaws and is commonly used with very small suture needles in cardiovascular, plastic, and neurosurgical procedures. Tungsten carbide micro cross-serrated tips firmly grip the small needle and assist with keeping it from twisting during suturing.

The Ryder Needle Holders TC are precision-engineered surgical instruments designed for secure needle handling and delicate suturing tasks. Manufactured with tungsten carbide (TC) inserts, these needle holders ensure exceptional grip strength, durability, and control, making them a preferred choice in microsurgery, cardiovascular, and plastic surgery. Supplied globally by NAZMED SMS SDN BHD under the trusted SMS brand, they are part of the advanced Tungsten Carbide Inserts collection trusted by surgeons worldwide.

The Ryder Needle Holders TC are specifically crafted to deliver precision, reliability, and safety during suturing in delicate surgical fields. Their slim-profile jaws with tungsten carbide inserts provide a non-slip grip on fine suturing needles, reducing the risk of twisting or slippage. Built from high-quality stainless steel, these needle holders are corrosion-resistant, autoclavable, and durable under frequent use.

Product Use Cases & Clinical Relevance

These needle holders are highly valued in:

- Cardiovascular surgery for fine suturing of vessels and tissues

- Plastic and reconstructive procedures requiring precision needle control

- Microsurgical applications involving delicate anatomical structures

- General surgeries where accuracy and grip reliability are essential

The TC inserts enhance jaw strength and extend the instrument’s service life, making them a cost-effective and dependable tool for surgical teams.

Ergonomic & Material Design Highlights

- Tungsten Carbide Jaw Inserts: Provide superior needle grip and resistance to wear

- Slim Profile Jaws: Allow secure handling of fine needles

- Ergonomic Handles: Reduce surgeon fatigue during prolonged procedures

- High-Grade Stainless Steel: Ensures corrosion resistance and repeated sterilization safety

- Precision Locking Mechanism: Maintains secure needle holding without slippage

Benefits for Medical Professionals

- Provides maximum control in delicate suturing tasks

- Reduces risk of needle slippage or breakage

- Long-lasting performance with reinforced TC jaws

- Reliable in both general and highly specialized surgeries

- Globally trusted across Asia, Europe, Africa, the Middle East, and the Americas

NAZMED SMS SDN BHD is a leading global supplier of surgical medical supplies, delivering precision instruments that meet international quality standards. The SMS brand stands for trust, innovation, and surgical excellence, ensuring surgeons worldwide have access to instruments that deliver consistent, reliable performance. Learn more about our tungsten carbide surgical instruments and explore insights in our product blog.

By choosing Ryder Needle Holders TC, surgeons gain a tool that ensures accuracy, safety, and long-term reliability in every suturing procedure.

Key Features

- Premium Ryder Needle Holders reinforced with TC inserts

- Secure grip on fine suturing needles

- Slim-profile jaws for precision suturing

- Tungsten carbide tips ensure durability and extended life

- Ergonomic design reduces hand fatigue during long surgeries

- Manufactured from premium stainless steel

- Resistant to corrosion and sterilization wear

- Ideal for cardiovascular, microsurgery, and plastic surgery

- Reliable performance in delicate surgical fields

- Supplied worldwide by NAZMED SMS SDN BHD under the SMS brand

Ryder Needle Holders TC, SMS brand, surgical instruments, tungsten carbide inserts, NAZMED SMS SDN BHD, surgical medical supplies, TC needle holders, microsurgery needle holders, cardiovascular needle holders, fine suturing instruments, tungsten carbide surgical instruments.